Galvanic CP – Zinc Anodes

Galvanic CP – Zinc Anodes

Zinc anodes are the oldest sacrificial anodes and first used by Sir Humphrey Davy about 1824. Zinc anodes (zinc alloys) are for two general applications; fresh waters/soil and seawater/brackish water. Although zinc anode current capacity is low, the capacity is independent of current density compared to other galvanic anodes. Furthermore, Its efficiency is relatively high (between 90-95%). Even at a current density as low as 50 mA/m² (5 mA/ft²) an efficiency of 90% or more is expected. Zinc anode with a gypsum and bentonite backfill may make it more cost effective than Magnesium anodes due to its high efficiency.

However, the high temperature and chemistry of the environment (presence of bicarbonates, carbonates or nitrates) could result more noble potentials of the anode.

APPLICATION

- To avoid bi-metallic corrosion of associated structures.

- To mitigate voltages introduced in pipelines by adjacent overhead AC power lines.

- Corrosion control of underground metallic structures.

In grounding earthing application of zinc anodes, packaged anode where the anode has a high length to weight ratio in order to minimize its ohmic resistance to ground.

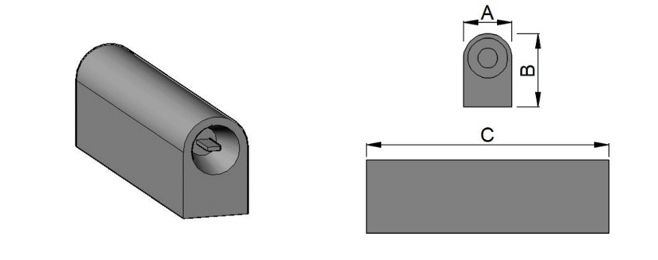

KORTEK standard production and main stock of zinc anodes for buried applications are as below;

| Product Code |

Bare Anode Weight, kg |

Width - A (mm) |

Heigth - B (mm) |

Length - C (mm) |

|---|---|---|---|---|

| ZN-D01 | 8 | 35 | 30 | 1140 |

| ZN-D02 | 12 | 30 | 40 | 1530 |

| ZN-D03 | 35 | 60 | 60 | 1480 |

| ZN-D04 | 53 | 75 | 70 | 1485 |

| ELECTROCHEMICAL PROPERTIES | |

|---|---|

| Potential wrt Cu/CuSO4 | 1.10 Volts |

| Output Capacity | 780 A.hour/kg |

| Current Efficiency | 95% |

| Consumption | 11.2 kg/A.year |

| ALLOY COMPOSITION | |

|---|---|

| Metals | Standard |

| Aluminum | 0.005 % max |

| Cadmium | 0.003% max |

| Iron | 0.0014% max |

| Copper | 0.002% max |

| Lead | 0.003% max |

| Zinc | Remainder |