Galvanic CP – Aluminum Anodes

Aluminum anode working performance could be sorted as well for the salty environment and decent for the fresh water and lower levels of brackish water. The reason why the aluminum works better in the salty environment is due to it requires chloride ions in the electrolyte to function properly. As the chloride ions decrease as the capacity of the anode decreases. Aluminum anodes last longer than zinc anodes and provides more protection. Because of their relatively high current capacity and light weight, aluminum anodes have virtually replaced zinc in seawater applications. In addition, the aluminum anodes are not pollute and does not contaminate the electrolyte.

All type of aluminum anodes are offered in our production line; bracelet anodes for offshore pipelines, standoff anodes for platforms, eye-bolt and threaded stud anodes for pier, piling, and heater-treater applications, and flush-mount anodes for hulls and special applications.

KORTEK supplies series of aluminum anodes for defend the corrosion of steel structures in seawater. The performance of anode is affected by the chemical composition of the alloy. We adopt high purity of aluminum ingot for the anodes. The anodes are casted automatically, thus the anode alloy is uniform, free of dust and oxides.

Production is carried our according to the international standards and as specified in Client specifications as DNVGL B401 and EN 12496.

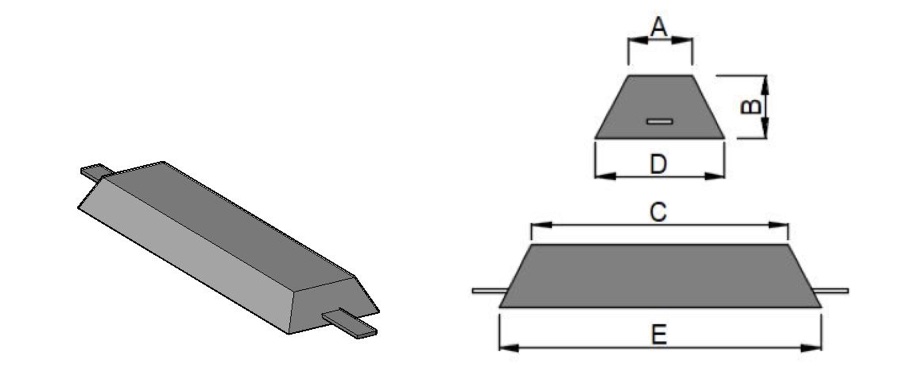

KORTEK standard production and main stock of aluminum anodes as flush mounted for sea water applications are as below;

| Product Code | Net Weight (Kg) |

Width 1-A (mm) |

Height 1-B (mm) |

Length 1-C (mm) |

Width 2-D (mm) |

Length 2-E (mm) |

|---|---|---|---|---|---|---|

| AL-FL01 | 0,5 | 50 | 30 | 200 | 50 | 200 |

| AL-FL02 | 1 | 66 | 30 | 280 | 75 | 290 |

| AL-FL03 | 2,5 | 120 | 40 | 270 | 120 | 270 |

| AL-FL04 | 3,5 | 35 | 35 | 1140 | 35 | 1140 |

| AL-FL05 | 3,8 | 105 | 35 | 375 | 130 | 385 |

| AL-FL06 | 4 | 150 | 30 | 350 | 150 | 350 |

| AL-FL07 | 4,6 | 85 | 80 | 275 | 106 | 310 |

| AL-FL08 | 4,75 | 80 | 60 | 280 | 110 | 315 |

| AL-FL09 | 5 | 60 | 80 | 270 | 110 | 310 |

| AL-FL10 | 5,8 | 80 | 78 | 270 | 115 | 315 |

| AL-FL11 | 6 | 80 | 95 | 270 | 120 | 330 |

| AL-FL12 | 6,5 | 115 | 52 | 355 | 150 | 385 |

| AL-FL13 | 10,5 | 120 | 70 | 445 | 140 | 500 |

| AL-FL14 | 13 | 105 | 75 | 540 | 130 | 615 |

| AL-FL15 | 15 | 115 | 90 | 460 | 155 | 500 |

| AL-FL16 | 18 | 130 | 100 | 600 | 130 | 600 |

| AL-FL17 | 20 | 155 | 80 | 495 | 210 | 540 |

| AL-FL18 | 20 | 105 | 70 | 1125 | 105 | 1125 |

| AL-FL19 | 20 | 35 | 75 | 1415 | 70 | 1425 |

| AL-FL20 | 24 | 160 | 95 | 500 | 215 | 540 |

| AL-FL21 | 25 | 160 | 80 | 675 | 210 | 710 |

| AL-FL22 | 27 | 190 | 90 | 485 | 205 | 515 |

| AL-FL23 | 28 | 205 | 140 | 500 | 205 | 500 |

| AL-FL24 | 29 | 150 | 100 | 670 | 210 | 715 |

| AL-FL25 | 30 | 155 | 100 | 665 | 215 | 715 |

| AL-FL26 | 30 | 190 | 115 | 475 | 210 | 525 |

| AL-FL27 | 34 | 155 | 95 | 715 | 215 | 780 |

| AL-FL28 | 36 | 160 | 105 | 675 | 225 | 720 |

| AL-FL29 | 40 | 155 | 110 | 1500 | 155 | 1500 |

| AL-FL30 | 40 | 140 | 120 | 1040 | 140 | 1040 |

| AL-FL31 | 44 | 170 | 120 | 715 | 230 | 805 |

| AL-FL32 | 45 | 175 | 120 | 710 | 230 | 800 |

| AL-FL33 | 49 | 170 | 125 | 710 | 230 | 800 |

| AL-FL34 | 50 | 190 | 125 | 780 | 235 | 855 |

| AL-FL35 | 60 | 190 | 140 | 810 | 240 | 890 |

| AL-FL36 | 62 | 190 | 130 | 800 | 240 | 890 |

| AL-FL37 | 70 | 190 | 145 | 810 | 245 | 900 |

| AL-FL38 | 72 | 190 | 145 | 810 | 245 | 900 |

| Al-FL39 | 74 | 185 | 155 | 805 | 225 | 900 |

| Al-FL40 | 75 | 190 | 155 | 800 | 245 | 900 |